Job Descriptions:

Pondmen

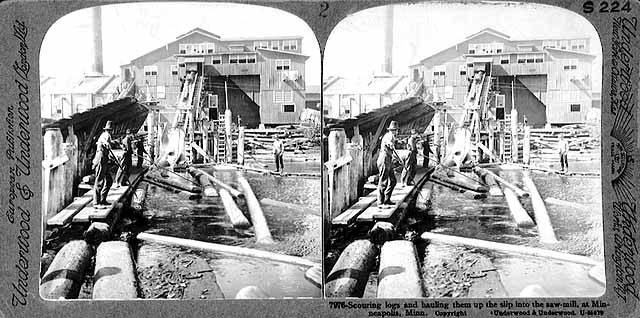

Scouring logs and hauling them up the slip into a Minneapolis sawmill, 1920.

Minnesota Historical Society Photograph Collection, Location no. HD5.5 r41 Negative no. 78626

"The men working on the pond propel the logs to the foot of the incline and start them on the chain which carries them up to the log deck in the mill. They stand on a board walk barely above the surface of the pond, on a small flatboat, or even on the floating logs themselves to do their work, and use a pike pole with which to propel the logs."

—U.S. Department of Labor

U.S. Department of Labor, Bureau of Labor Statistics. Wages and Hours of Labor in the Lumber, Millwork, and Furniture Industries, 1890 to 1912 (Washington, D.C.: Government Printing Office, 1913).

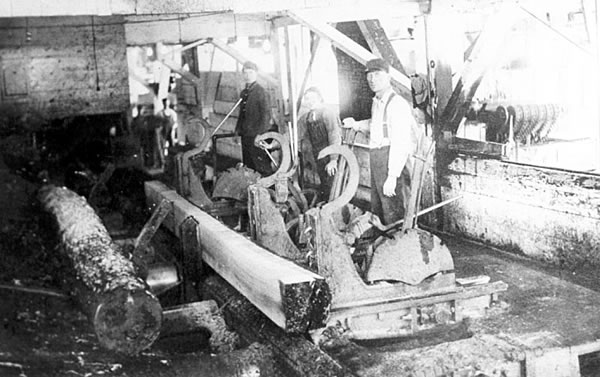

Chief Sawyer

Lumber operations at a mill in Winton, MN, ca. 1905.

Minnesota Historical Society Photograph Collection, HD5.5 p11

"The successful working of the entire plant depends upon the the sawyer more than upon any other one wageworker in the mill."

—U.S. Department of Labor

In 1911, sawyers worked an average of 60 hours each week in season at 70 cents an hour.

U.S. Department of Labor, Bureau of Labor Statistics. Wages and Hours of Labor in the Lumber, Millwork, and Furniture Industries, 1890 to 1912 (Washington, D.C.: Government Printing Office, 1913).

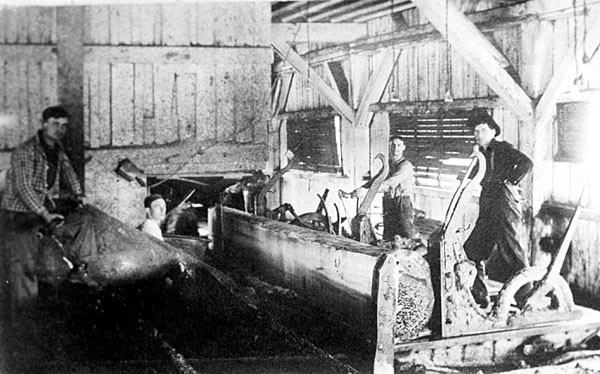

Dogger and Setter

Lumber operations at a mill in Winton, MN, ca. 1905.

Minnesota Historical Society Photograph Collection, HD5.5 p11

"The work on the carriage requires two or more men, who are known as setters and doggers....

The dogger secures the log in place by means of barbs or "dogs" located in the headblocks of the carriage. These "dogs" are operated through levers, by which a downward movement drives them into the log and secures it in place., while an upward movement releases it for turning, etc.

It is the duty of the setter to move the log into position for each successive line to be sawed. He does this by means of a rachet connected with the headblocks by a shaft and cogs. The ratchet is turned by a lever and it has a graduated dial and indicator by which the setter determines when the log is in position for the desired cut."

—U.S. Department of Labor

U.S. Department of Labor, Bureau of Labor Statistics. Wages and Hours of Labor in the Lumber, Millwork, and Furniture Industries, 1890 to 1912 (Washington, D.C.: Government Printing Office, 1913).